The stopping system is probably the most vital safety and security feature in any type of vehicle. Ensuring its optimum performance pivots dramatically on the top quality and integrity of its components, foremost among them being the brake pads. Brake pad suppliers play a pivotal role in this environment, not equally as manufacturers of friction products yet likewise as vital service providers to the auto sector and, indirectly, to automobile owners. Comprehending the diverse solution provided by these suppliers, beyond just creating items from a brake pad manufacturing facility, is vital for appreciating their payment to roadway security.

At its core, the key "service" of a brake pads maker is the design, growth, and manufacturing of top quality brake pads. This includes a intricate interaction of product science, design, and extensive screening. Makers spend heavily in r & d to create friction products that use ideal stopping power, toughness, sound reduction, and discolor resistance across a wide range of driving conditions and vehicle kinds. This study incorporates exploring numerous raw materials, consisting of organic, semi-metallic, and ceramic substances, and thoroughly evaluating their performance characteristics.

The brake pad factory itself is a advanced procedure. Modern making centers utilize sophisticated machinery and quality control procedures to make sure constant and accurate manufacturing. This consists of automated mixing of basic materials, accurate molding and pushing of the pad forms, warm treatment for optimum product homes, and the application of backing plates and friction shims. Strict top quality checks are executed at every phase of the manufacturing process, from inbound material assessment to final product testing, to ensure that each set of brake pads meets or surpasses sector requirements and regulative requirements.

However, the service supplied by brake pad makers expands far past the physical production of the pads. They function as essential companions to different stakeholders in the auto industry:.

Original Devices Suppliers (OEMs): Brake pad suppliers function carefully with vehicle producers (OEMs) to create and provide brake pads particularly customized to their automobile versions. This often involves joint engineering efforts, where the brake pad design is maximized for the vehicle's weight, braking system components (calipers, blades), and designated performance features. OEMs rely on the knowledge and integrity of brake pad manufacturers to ensure that the braking systems in their vehicles satisfy rigorous security and efficiency requirements right from the factory. This collaboration includes ongoing communication, technical assistance, and frequently, just-in-time shipment to fulfill manufacturing timetables.

Aftermarket Suppliers and Distributors: The aftermarket for brake pads is significant, dealing with car proprietors needing substitute components. Brake pad manufacturers service this section via a network of suppliers, wholesalers, and stores. Their solution to these partners consists of giving a constant supply of top notch brake pads, offering detailed item brochures and technical details, and usually supplying advertising and marketing and sales support. Reliable logistics and trustworthy supply chains are crucial elements of this service, making sure that replacement brake pads are easily offered to auto mechanics and consumers when required.

Automotive Technicians and Repair Work Shops: While not direct customers, vehicle service technicians are essential intermediaries who set up and suggest brake pads. Brake pad suppliers support these specialists by supplying clear installation directions, technological specifications, and fixing overviews. Some suppliers also use training programs and technical assistance hotlines to aid service technicians with any issues they may run into. The convenience brake pad factory of setup and the integrity of the brake pads directly impact the performance and track record of repair shops.

End Consumers (Vehicle Owners): Ultimately, the solution of a brake pad manufacturer influences the safety and peace of mind of automobile proprietors. By producing dependable and high-performing brake pads, they contribute directly to roadway safety. While customers may not directly communicate with the supplier, they benefit from the quality assurance, sturdiness, and performance engineered right into the item. Clear labeling, helpful product packaging, and easily available product details online likewise contribute to the total solution offered to the end customer.

Beyond these core services, some leading brake pad manufacturers use extra value-added solutions:.

Study and Technology: Continual financial investment in R&D to develop new friction products that are more eco-friendly (e.g., low-copper or copper-free formulas), offer boosted performance (e.g., boosted stopping power or longer life-span), or decrease noise and vibration.

Technical Training and Assistance: Providing training programs for technicians on the correct installment and maintenance of brake pads, along with offering technological support to resolve details problems.

Customized Solutions: Collaborating With OEMs or specialized automobile modifiers to establish brake pads customized to special efficiency needs.

Ecological Obligation: Carrying out sustainable manufacturing techniques, minimizing waste, and sticking to environmental guidelines.

Service Warranty and After-Sales Assistance: Providing warranties on their products and offering support in case of issues or early wear.

Finally, the service offered by brake pad makers is a multifaceted and important element of the vehicle industry. It expands much past the physical outcome of a brake pad manufacturing facility, encompassing layout, design, extensive screening, efficient supply chain administration, technological assistance for sector companions, and inevitably, contributing to the safety and security and satisfaction of automobile proprietors. Their dedication to quality, advancement, and cooperation with numerous stakeholders makes certain that cars when traveling are geared up with trustworthy and reliable stopping systems, highlighting their crucial role in vehicle safety.

Lark Voorhies Then & Now!

Lark Voorhies Then & Now! Keshia Knight Pulliam Then & Now!

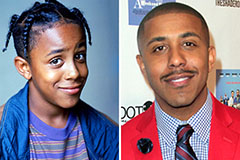

Keshia Knight Pulliam Then & Now! Marques Houston Then & Now!

Marques Houston Then & Now! Samantha Fox Then & Now!

Samantha Fox Then & Now! Brooke Shields Then & Now!

Brooke Shields Then & Now!